This method involves strengthening the ground using high deformation modulus CSC® (Controlled Stiffness Column) concrete displacement columns.

Common uses

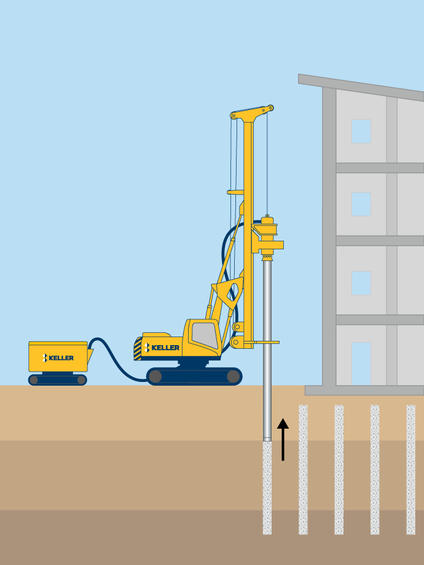

Process

The columns are made through a compressible substrate up to load-bearing layers to reduce settling and increase load-bearing capacity.

The effectiveness of ground improvement depends on the stiffness relationship between the soil and columns. Load from the structure is transferred to the ground and columns through a load transfer platform or rigid foundation.

After the working platform is prepared, the rig is moved into place. Generally a displacement auger or vibrated tube is used to penetrate down to the designed depth. Concrete is pumped as the tool is pulled upwards.

The concrete flows out of the tube and supports the bore, and after hardening forms the core of the column.

If the concrete is fresh, cutting of column heads is done mechanically. Once the concrete has hardened, we do it by a hand.

Advantages

Quality assurance

Rigid inclusions elements are controlled before, during and after installation to ensure the highest quality of solution. A variety of tests can be carried out including:

- Trial fields for verifying columns production parameters

- Digital recording and logging of the execution parameters

- Column integrity test, column load test, column material compressive strength tests, column diameter verification

The type and frequency of tests varies based on the size of the project and the geotechnical context.